The coronavirus crisis has highlighted the need for Additive Manufacturing in the healthcare sector as a flexible and ideal solution for emergencies.

Producing faster, highlighting design, manufacturing on demand… These days, the advantages of 3D printing, already familiar to the industrial sector, are also surprising the healthcare sector.

Hospitals and healthcare institutions are demanding materials so their professionals can continue treating the thousands of people infected with Covid-19 in Spain. These resources, in most cases, are insufficient and arrive only in dribs and drabs. Masks, respirators, visors, and so on, are now indispensable for healthcare workers at the end of their tether. Hence, 3D printing projects and initiatives have been launched to support the sector.

“We have already begun working with requests from hospitals desperately requesting materials,” says Miguel Ángel Mora, engineer responsible for 3D Engineering Services at Grupo Solitium. He also explains that in terms of healthcare resources, designs and materials must meet certain requirements and have specific properties, and therefore not all technologies are proving to be efficient in this area.

The 3D Solution

3D printing has proven to be a fast and flexible solution for emergencies. “It allows many things to be manufactured quickly, prototypes, final parts… from PPE to respirators,” says Adrián Estaún, 3D Sales Director at Grupo Solitium. However, there are certain minimum qualities required for these parts to be considered useful in hospitals. “FDM technology, for example, has proven inefficient for the manufacture of masks because it is not a watertight material and, therefore, allows the virus to pass through,” explains Mora. “In this sense, the polyamide fusion technology used by HP’s Jet Fusion 3D technology is functional, as the resulting part is watertight, an essential property for this specific application,” explains the Grupo Solitium engineer.

Additive Manufacturing also adds strategic points because it allows for local design and manufacturing, which eliminates dependence on imports from other countries such as China. And in contingency plans like the one Spain is currently experiencing, it is essential to have technology that offers rapid, local solutions.

However, producing medical supplies that are so necessary in hospitals right now using additive manufacturing is not easy. First, due to the lack of raw materials, but also due to the lack of all the prior analysis, design, and testing required in these cases. As is the case in the IT field, when designing contingency plans, it is essential to invest in servers, backups, and other proven systems. And in terms of Additive Manufacturing, the response to the health crisis should have been tested beforehand to consider its efficiency. Hence the need for investment in this technology.

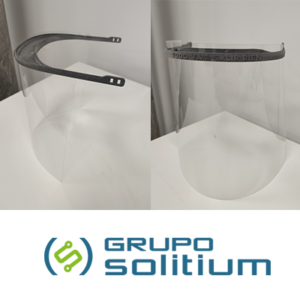

Even so, companies like Grupo Solitium have put their experts and engineers to work to provide solutions to requests coming in from hospitals, and currently, “we are already manufacturing support visors for protective screens. A part without regulatory commitment and that we can produce in both polyamide and other materials,” explains Mora. The engineer responsible for 3D Engineering Services at Grupo Solitium says he has already put 240 units of this visor into production per day on his own HP Jet Fusion equipment, and at some of his client companies that use this technology, such as InMake and Microdental.

The need for 3D production of medical supplies these days is highlighting the effectiveness of this technology in emergencies. Therefore, healthcare systems, both public and private, must be prepared in this regard. But also, “we should standardize libraries of STL models (files for 3D printing) that everyone can use when needed,” argues Adrián Estaún. An emergency like the current one will pass, but no one guarantees that something similar won’t happen again. Therefore, we must prepare to avoid making the same mistakes.