A new material will reduce the repair of aeronautical parts from days to minutes.

NEOCROSS, as the new composite is called, will reduce production and maintenance costs.

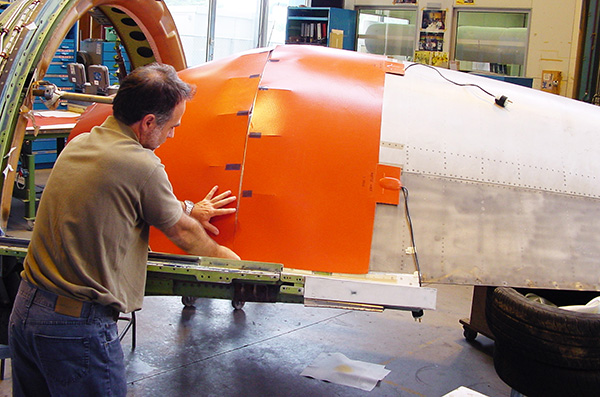

Cidetec Surface Engineering is immersed in the development of a new material for the aeronautical and energy industries that will significantly reduce maintenance costs and time. This research is part of the NEOCROSS project, which aims to develop and offer a new generation of high-performance epoxy composites and adhesives with disassembly capabilities. These new composites will be manufactured using traditional methods, but unlike current methods, they can be easily disassembled and repaired by applying heat and pressure to the damaged area.

The composites to be developed in the NEOCROSS project retain all the advantages of conventional thermosets—high thermal and mechanical performance—but also offer all the benefits of the 3R technology developed by Cidetec: repairability, reprocessability, and recyclability. This is possible thanks to an innovative thermoset resin system containing dynamic bonds, responsible for the 3R properties.

One of the greatest advantages offered by NEOCROSS is the repairability of manufactured parts, which avoids most of the drawbacks of current composite repair technologies. This new material is repaired by applying heat and pressure using a portable repair tool. This allows operations that previously took hours, or even days, to be completed in minutes, achieving 100% property recovery. Furthermore, the innovative NEOCROSS detachable adhesive will allow easy separation of damaged parts, enabling the disassembly of delaminated parts for repair.

NEOCROSS innovations will lead to the development of faster and more cost-effective repair technologies for composite delaminations, both in production and in service, and will also allow for the recovery of rejected parts from manufacturing. All of this will lead to cost savings for airlines, as well as for wind turbine manufacturers and maintenance centers.

The NEOCROSS project, “New epoxy matrix composite with repair properties through dynamic crosslinking,” co-funded by member countries within the EUREKA framework and by the European Commission, will conclude in 2023. The project is coordinated by GAIRESA and includes, along with Cidetec Surface Enginering, SOFITEC, GMI Aero SAS, and RESCOLL.

EC International Group: excellence in prototyping and small-batch production, from metal to plastic

EC International Group: Excellence in Prototyping and Small-Series Production, from Metal to Plastic In an industrial environment that increasingly demands performance, agility, and quality, combining

On the sofa with… Eduardo de la Guerra – Project Manager at Talgo in the Innovation Department | Talgo

On the sofa with… Eduardo de la Guerra – jefe de proyectos en talgo en la dirección de innovacion | Talgo

On the sofa with… Silvia Leal

On the sofa with… Silvia Leal, Experta en Tendencias de Futuro & Inteligencia Artificial, Asesora de OCDE & UE, Keynote Speaker

Behind the innovations: Jaime Ruesca, CEO de PRISMACIM

Jaime Ruesca – CEO Prismacim 1. What motivated you to start developing this product? At Prismacim, we contribute to the development of innovative products in