Hexagon introduces the ultimate CMM laser scanning, offering manufacturers 70% faster inspection and high accuracy

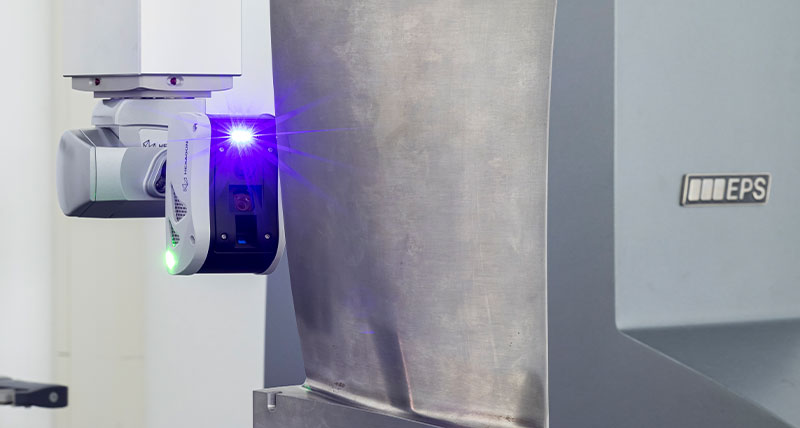

Hexagon’s Manufacturing Intelligence division has just introduced the HP-L-10.10, a cutting-edge non-contact laser sensor for coordinate measuring machines (CMMs) that offers manufacturers the ability to perform dimensional measurements with accuracy comparable to tactile probing and inspection on almost any surface in a fraction of the time.

Manufacturers using CMMs to measure critical parts have become accustomed to trading speed for accuracy. The HP-L-10.10 sensor uses Hexagon’s latest inter-platform laser line scanning technology to deliver repeatability and performance comparable to tactile measurements performed on the same CMM. It can also measure 600,000 individual points per second with a probing error of just 8 μm, quickly capturing a complete, high-resolution digital representation of the part that is suitable for both surface and detailed feature inspection. Although laser scanning has been possible on CMMs, the HP-L-10.10 is seven times faster than its predecessor and features high-precision scanning.

The new sensor uses Hexagon’s exclusive SHINE (Systematic High-Intelligence Noise Elimination) technology, allowing scanning of almost any surface or part finish with maximum speed and accuracy without user intervention.

“We believe this laser line scanner is a game-changer, offering speed, flexibility, and accuracy without sacrificing one crucial inspection need for another,” said Patryk Wroclawski, Product Manager for Non-Contact Triangulation and Laser. “The HP-L-10.10 redefines what can be achieved with a single piece of equipment, allowing our customers to use detailed measurement data for actions beyond final part quality, whether that’s new product development or continuous improvement initiatives.”

The HP-L-10.10 complements Hexagon’s extensive offering of sensor solutions for CMMs, offering manufacturers greater flexibility in their projects with the confidence that their CMM investment can address the widest range of measurement applications, from large sheet metal parts to intricate electric vehicle components. It is available for the GLOBAL S productivity line and GLOBAL Advantage CMMs.

Developed in close collaboration with the team, Hexagon’s PC-DMIS inspection software allows users to automatically produce efficient laser scanning paths by automatically generating the tips, scans, and motions required for measurement. The software can capture a single point cloud with varying density in a single motion, valid for both surface and detailed feature inspection. Users can easily visualize surface imperfections, taking full advantage of the scanner’s multifaceted capabilities to identify perceived quality issues and fuel continuous process improvement.

When measuring large parts or remotely programming the CMM, the user experience is significantly enhanced with a built-in overview camera (OVC), which provides a clear view of the work area with visible guides on the part indicating the measurement range. The visible guides warn the quality technician when the measurement range is exceeded, enabling simpler routine creation and inspection via PC-DMIS software. The overview camera also improves productivity and collaboration during inspection, for example by photographing the surface of a part that is out of tolerance so the operator and production colleagues can quickly locate the problem.

The HP-L-10.10 laser line scanner is now available worldwide. Visit Hexagon’s new microweb “Can I Measure It?” for resources explaining how measurement challenges can be addressed through more effective strategies and the improved use of CMM and sensor technologies.

EC International Group: excellence in prototyping and small-batch production, from metal to plastic

EC International Group: Excellence in Prototyping and Small-Series Production, from Metal to Plastic In an industrial environment that increasingly demands performance, agility, and quality, combining

On the sofa with… Eduardo de la Guerra – Project Manager at Talgo in the Innovation Department | Talgo

On the sofa with… Eduardo de la Guerra – jefe de proyectos en talgo en la dirección de innovacion | Talgo

On the sofa with… Silvia Leal

On the sofa with… Silvia Leal, Experta en Tendencias de Futuro & Inteligencia Artificial, Asesora de OCDE & UE, Keynote Speaker

Behind the innovations: Jaime Ruesca, CEO de PRISMACIM

Jaime Ruesca – CEO Prismacim 1. What motivated you to start developing this product? At Prismacim, we contribute to the development of innovative products in